Description

- Product implementation standards

Q/RTL13-2023

- Product characteristics and uses

This product is used for DC distribution circuit of 150 kV and below, as a power connection line between rectifier transformer and electrostatic precipitator, with waterproof, stable electrical performance, superior anti-aging performance, long service life, widely used in metallurgy, electric power, petrochemical and other industries.

- Use features

Rated DC voltage: 50-150 kV

Cable installation and laying temperature shall not be less than 0℃

Allowable bending radius of the cable: minimum: 15 times the outer diameter of the cable

- Basic model and name

| model | name |

| YJVC22-75KV | Rated voltage 75kV copper core crosslinked polyethylene insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

| YJVC22-100KV | Rated voltage of 100kV copper core crosslinked polyethylene insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

| YJVC22-150KV | Rated voltage of 150kV copper core crosslinked polyethylene insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

| YJ L VC22-75KV | Rated voltage of 75kV aluminum core xLPE insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

| YJ L VC22-100KV | Rated voltage 100kV aluminum core crosslinked polyethylene insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

| YJ L VC22-150KV | Rated voltage 150kV aluminum core crosslinked polyethylene insulated steel strip armored PVC sheath

DC high-voltage dust filter cable |

- Code name and meaning

Product model and specification representation are shown in the following figure:

Product code: copper conductor…. omitted

L, aluminum conductor

YJ, indicates cross-linked polyethylene insulation

V, means the PVC sheath

C, means the dust filter cable

22, means steel strip armor

2) Rated voltage: 150 means 150 kV and below

3) Nominal section: (50) represents 50mm2

Example: a) YJVC22-150 (50)

Represents a rated voltage of 150kV, 50mm2Copper core crosslinked polyethylene insulated steel strip armoured PVC sheathed DC high voltage dust filter cable

b)YJLVC-150(95)

Represents the rated voltage of 150kV, 95mm2Aluminum core crosslinked polyethylene insulated PVC sheath DC high voltage dust filter cable

- Main technical indicators

(1) The conductor

The conductor shall be a stranded conductor (copper or aluminum).

structure

- A) The conductor structure shall comply with the second stranded conductor in GB / T3956 standard. Non-compacted circular conductors or compacted circular conductors may be used.

- B) The surface of the conductor shall be clean without oil or burr.

- C) The core is concentric, the adjacent layer is inverted, and the outer layer must be left.

In d), only single line welding is allowed in the wire core, and only one solder joint is allowed in any stranded joint length in the same layer.

- E) The joint shall be trimmed without burr and the outer diameter of the core shall not exceed the maximum outer diameter.

- F) The conductor wire core shall comply with the provisions of Table 3

- Single-core cable with a second stranded copper (aluminum) conductor

| nominal cross

mm2 |

Minimum number of single lets in the conductor | Max. conductor resistance at 20℃

Ω/km |

||||

| circular | Pressure round | |||||

| copper | aluminium | copper | aluminium | copper | aluminium | |

| 50 | 19 | 19 | 6 | 6 | 0.387 | 0.641 |

| 70 | 19 | 19 | 12 | 12 | 0.268 | 0.443 |

| 95 | 19 | 19 | 15 | 15 | 0.193 | 0.320 |

Structural inspection

Inspection and measurement shall be conducted to check whether the structure complies with the requirements of 5.1.1 and 5.1.2 and GB / T3956.

resistance

- A) The DC resistance of the cable conductor per core shall comply with the requirements of GB / T3956.

Bit) Compliance shall be checked according to the test method specified in Article 2.1 of GB5023.2.

For c) the conductor DC resistance is shown in Table 3.

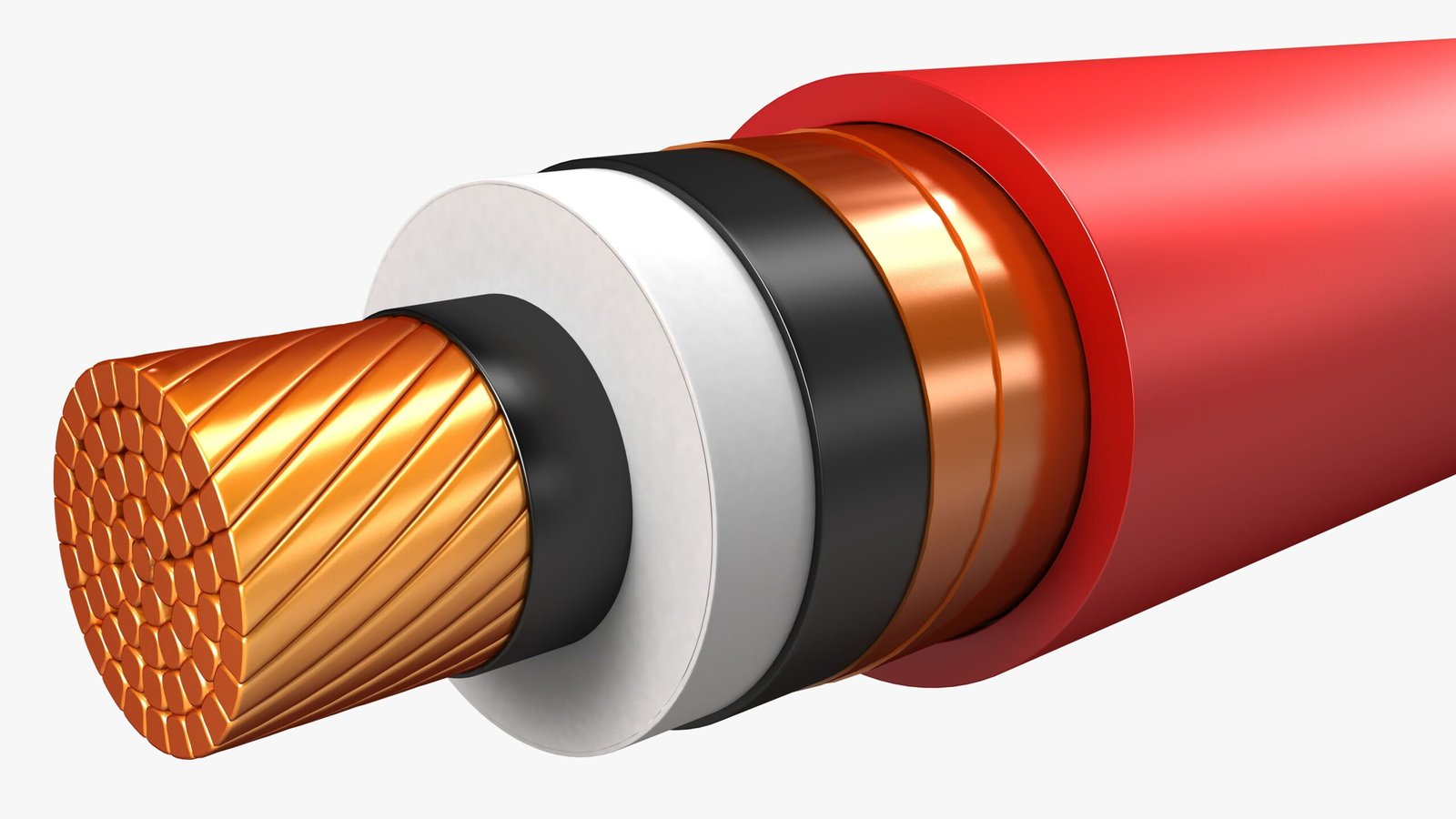

Conductor shielding layer

A shield layer of the semi-conductive conductor should be squeezed outside the conductor.

The inner shielding layer can be made of semi-conductive polyethylene material, and the main technical properties of the semi-conductive polyethylene material shall meet the requirements of Annex A.

The minimum thickness of the inner shield is approximately 0.6mm.

(2) Insulation

material

Cable insulation shall be imported high voltage cross linked polyethylene, high voltage cross linked polyethylene insulation properties, see Appendix B.

extruded insulation

The insulation shall be tightly packed on the conductor or conductor shielding layer. There shall be no air gap, shrinkage hole and impurities on the insulation cross section, and the surface shall be smooth, smooth and uniform in color.

insulation thickness

The insulation thickness shall meet the nominal value specified in Table 4, and any point of the insulation thickness may be less than the specified value, but not less than the 90%-0.1mm of the specified value.

Compliance shall be checked according to the test method specified in Article 8.1 of GB / T2951.1. One section of cable sample shall be taken at least 1 m apart.

- construction of cable

| model | Conductor section

mm2 |

The conductor shield thickness is mm | Nominal thickness of the insulation layer

mm |

Thickness of the insulating shield layer

mm |

The nominal thickness of the sheath

mm |

Cable with a maximum outer diameter of mm |

| YJ (L)VC22-150(50)

YJ (L)VC22-150(70) YJ (L)VC22-150(95) |

50

70 95 |

1.0

1.0 1.0 |

9.0

9.5 10.0 |

0.6

0.6 0.6 |

2.5

2.5 2.5 |

40

45 47 |

Strength requirement of the internal electric field of the cable

E=U / ((x + r) ln (R / r)) Structural design requirements E<13.2KV/mm

U is the voltage, R is the outer electrode radius, r is the inner electrode radius, and X is the distance from the r surface to R where the maximum field strength appears on the inner electrode surface, where X=0.

- insulation shielding

The cable shall have an insulating shield layer.

The shielding layer can be made of semi-conductive polyethylene material, and the main technical properties of the semi-conductive polyethylene material shall comply with Annex A and requirements.

The insulating shield shall be evenly coated on the insulating surface; the surface shall be smooth without sharp corners, particles, burns or bruises.

The approximate value of the insulation shield is 0.6mm.

metallic screen

The cable shall have a metal shielding layer.

The metal shield layer consists of overlapping winding soft copper belt.

The metal shield layer shall be evenly wrapped on the surface of the insulating shield layer. The capping rate is greater than or equal to 15%.

(3) Cover

The thickness of the sheath shall meet the nominal value specified in Table 4, in which the thinnest thickness of the armored cable sheath shall be no less than the nominal 80%-0.2mm, and the thinnest thickness of the non-armored cable sheath shall be no less than the 85%-0.1mm of the nominal value.

The mechanical properties of the sheath shall comply with the provisions in Table 5.

- Physical and mechanical properties of the PVC sheath

| order number | Performance project | unit | performance index | experimental method |

| 1

1.1 1.2 |

Mechanical properties before aging

Minimum tensile strength Minminimum elongation |

N/mm2 % |

12.5 150 |

GB/T2951.11 |

| 2

2.1

2.2

|

Mechanical properties of the air oven after aging

Treatment condition: temperature time Tensile strength after aging: —— Minimum median value —— Maximum rate of change Break elongation after aging —— Minimum median value —— Maximum rate of change |

℃ h

N/mm2 %

% % |

100±2 7×24

12.5 ±25

150 ±25 |

GB/T2951.12 |

| 3 | zero-G test

Test condition and temperature time Most of the weight loss |

℃ h mg/cm2 |

80±2 7×24 2.0 |

GB/T2951.32 |

| 4 | Anti-cracking test

Test condition and temperature time end of test |

℃ h

|

150±3 1 indehiscent |

GB/T2951.31 |

| 5 | High temperature pressure test

Test condition and temperature time The deformation rate is the maximum |

℃ h % |

80±2 4 50 |

GB/T2951.31 |

| 6 | Low-temperature winding test temperature

bear fruit |

℃

|

-15

indehiscent |

GB/T2951.14 |

| 7 | Low-temperature tensile test temperature

The elongation rate is minimal |

℃

% |

-15

20 |

GB/T2951.14 |

| 8 | Low-temperature shock test temperature

bear fruit |

℃

|

-15

indehiscent |

GB/T2951.14 |

Electrical performance of cable

- A) The DC resistance of the cable conductor shall meet the provisions of Table 3

- B) Between the conductive wire core of the finished cable and the shielding braided layer shall be able to withstand the DC voltage test specified in Table 6, and the voltage bearing time of the cable shall not be less than 1 minute.

- The DC voltage test of the finished cable

| model | The DC test voltage is kV |

| YJ (L)VC22-150 | 200 |

Reviews

There are no reviews yet.